- Home

- Products

- Foam Cutters (CNC Contour Cutting Machines)

- Foam Cutter (CNC Foam Cutting Line, Model GV6-GHH8)

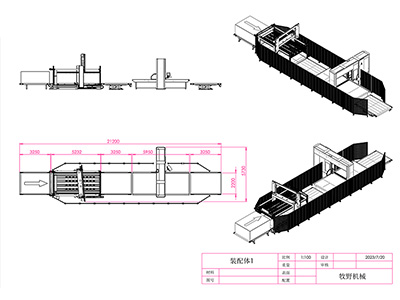

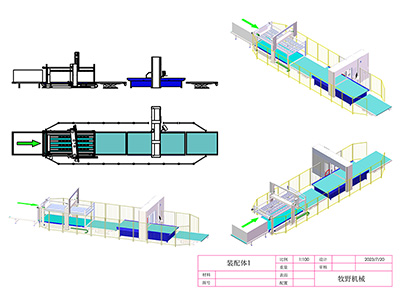

Foam Cutter (CNC Foam Cutting Line, Model GV6-GHH8)

GV6-GHH8 CNC foam cutting line is primarily designed for cutting sheet-shaped regular or irregular sofa foam cushions. The entire foam board can not only be cut into one version but also be automatically absorbed and separated to achieve multi-version cutting. This foam cutter is suitable for both single batch of large-quantity and multi batches of small-quantity applications, making it ideal for the sofa industry with an increasing trend of more batches and fewer quantities.

The irregularly shaped sofa foam cushions, as shown in the figure, have a volume of 500x2000x3000 for each batch with a thickness of 30mm for each foam block. The cutting cycle time for each batch is approximately 3-4 minutes, and the turnaround time is around 0.5 minutes. With an 8-hour workday, approximately 100 batches can be produced, resulting in a production capacity of 300 cubic meters of foam blocks per day.

The irregularly shaped sofa foam cushions, as shown in the figure, have a volume of 500x2000x3000 for each batch with a thickness of 30mm for each foam block. The cutting cycle time for each batch is approximately 3-4 minutes, and the turnaround time is around 0.5 minutes. With an 8-hour workday, approximately 100 batches can be produced, resulting in a production capacity of 300 cubic meters of foam blocks per day.

5 workers are required for this task. Additionally, an automatic nesting software is provided, which can generate a nesting diagram in less than 1 minute on average.

The regular-shaped sofa foam cushions, as shown in the figure, have a volume of 1000x2000x3000 for each batch with a thickness of 50mm for each foam block. The cutting cycle time for each batch is approximately 3-4 minutes, and the turnaround time for each batch is around 0.5 minutes. With an 8-hour workday, approximately 100 batches can be produced, resulting in a production capacity of 600 cubic meters of foam blocks per day.

6 workers are required for this task.

Technical Parameters

| Standard | Option | |

| Length of the foam block | 3000mm | 4500mm/5000mm |

| Height of the foam block | 1250mm | 1500mm |

| Width of the foam block | 2200mm | 2300mm |

| Work table | Conveyor belt worktable | |

| AC power | 380V 3 phase 4 wire | |

| Total power | 25KW | |

| Max. feeding speed | 40m/min | |

| Cutting precision | ±0.5mm | |

| Cutting tool | Air pressure: 6 bar Continuous blade Blade size: 10850mm×13mm×0.65mm (double-edge blade) Blade size (GV6): 10350mm×3.5mm×0.6mm Line speed: 15m/s | |

| Standard configuration | Worktable with loading conveyor L3300mm Standard GHH8 Lifting worktable with transfer conveyor L3300mm Standard GV6 Lifting worktable with unloading conveyor L3300mm Safety guard In-line control system | |

| Optional configuration | Automatic guide worktable | |

| Max. cutting speed | 100m/min (GHH8) 60m/min (GV6, depending on material being cut) | |